Features

Operations

TURNING BEASTS INTO BEAUTIES

When one thinks of aircraft that are selected to transport chieftains of industry or super celebrities around the world, three types come to mind – the Bombardier Global Express XRS, the Gulfstream G550 and the Falcon 7X. With acquisition costs that exceed US$50 million, these machines boast a range capability of at least 6,000 nautical miles at a cruise speed of Mach 0.80.

May 13, 2010 By Frederick K. Larkin

When one thinks of aircraft that are selected to transport chieftains of industry or super celebrities around the world, three types come to mind – the Bombardier Global Express XRS, the Gulfstream G550 and the Falcon 7X. With acquisition costs that exceed US$50 million, these machines boast a range capability of at least 6,000 nautical miles at a cruise speed of Mach 0.80.

|

|

| A Boeing Business Jet undergoing maintenance and interior refurbishment. PHOTO: Goderich Aircraft |

While these three models can comfortably carry eight passengers on 12-hour legs, some travellers prefer larger aircraft that provide truly palatial amenities such as a conference room, a stateroom complete with en suite washroom with shower, and seven-foot-high ceilings. They need an airliner.

The concept of a jet airliner performing as a business jet is not new. Back in April 1966, Tenneco took delivery of a BAC 1-11 from the factory. By 1980, Tenneco would have a trio of 1-11s and a Boeing 727-100 among its fleet of a dozen jets. In September 1966, Victor Comptometer received a 1-11 to replace its Vickers Viscount turboprop.

The first Douglas business jet was a new DC-9-15 delivered to the renowned investor Kirk Kerkorian in April 1968. Today, the 92-year-old Kerkorian owns a Boeing BBJ. Ling-Temco-Vought became the first operator of a corporate Boeing jet when it took delivery of a 737-200 in August 1969. A month later, Essex Wire received its 737-200. Playboy Enterprises got plenty of exposure in February 1970, when it bought a new DC-9-32. Nicknamed “Big Bunny,” it was painted black overall with the iconic Bunny logo in white emblazoned on its tail.

In 1970, only a dozen airliners operated as executive aircraft. This included eight BAC 1-11s, two 737-200s, a DC-9-15 and a DC-9-32. Forty years later, there are more than 350 airliners configured as VIP aircraft in commercial and military service around the world. Today, the largest corporate operated machines include two Boeing 777-200s and a Boeing 747-400 belonging to separate owners in the Middle East. Perhaps feeling somewhat constricted, the 747 owner has ordered an Airbus A380 that will have a MTOW of 1.2 million pounds.

While approximately 200 of these aircraft were delivered new, the others served with commercial carriers prior to becoming luxury liners. Modified models include Boeing 737-200/300/400/500s; 747-100/200/400/SPs; 757-200s; 767-200/300s; and 777-200s; Douglas DC-8-70s; DC-9-10/30/80s; as well as Airbus A310-300s and A340-200/500/600s. Not included in the 350 aircraft are regional jets produced by Bombardier and Embraer that have either been purchased new as executive aircraft or converted to serve that role.

The jet set

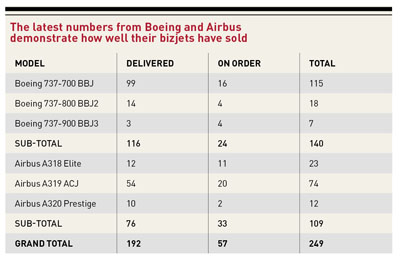

Since the introduction of the Boeing BBJ and the Airbus ACJ families in 1996 and 1997, respectively, these aircraft have been well received by the VIP market. Their buyers tend to be governments, private corporations and wealthy families. The lines between these three categories are sometimes blurred.

|

|

The aircraft are delivered to the owner/operator without an interior or sophisticated avionics in a so-called “green” configuration. It is the completion centre’s job to outfit the aircraft to the specifications provided by the owner, a task that can take up to a year to complete.

Around the globe there are approximately two dozen companies that have the expertise to complete a new airliner or to convert an older one. Besides having the necessary physical assets (significant hangar capacity), these companies require personnel that are talented in the disciplines of sheet metal fabrication, woodworking and upholstery in addition to having airframe and avionics skills. Another invaluable talent, mandatory within senior management, is a set of interpersonal skills that enables constructive face-to-face dealings with customers – most of whom are the antithesis of shrinking violets.

The largest North American completion centres specializing in airliners include: Associated Air Center in Dallas, Texas; Comlux Completion USA in Indianapolis, Ind.; Gore Design Completions in San Antonio, Texas; and L-3 Communications Integrated Systems in Greenville, Texas. The leading European outfits include Air France Industries in Le Bourget, France; Jet Aviation in Basel, Switzerland; and Lufthansa Technik in Hamburg, Germany.

It may come as a surprise that there is a company in southwestern Ontario that has been increasing its share of this specialized international market. Goderich Aircraft of Huron Park, Ont. (25 miles north of London), has completed/converted numerous airliners into bizjets in addition to its work on large cabin purpose-built jets such as Globals, Gulfstreams, Challengers and Falcons.

Can a small Canadian outfit compete against the established players in this niche? Before we attempt to answer that, it is useful to review how the company got to where it is today.

That was then…

Back in 1972, a Canadian named James T. Field, who had served as a mechanic with the U.S. Air Force in southeast Asia, started an aircraft maintenance business called Brant Aero in Brantford, Ont. His eldest son Blaine worked there for a decade until 1993, when the entrepreneurial urge took hold. Blaine created an outfit on the same field that specialized in interior refurbishments, but would also repaint aircraft and perform required maintenance while an aircraft was in its shop. Blaine later moved the operation to Goderich, Ont., but it would be a short stay, as a better opportunity presented itself in 1997. That’s when he moved the company to Centralia Airport at Huron Park, Ont. The headcount stood at 50 at that time.

|

|

| An interior of a Gulfstream G550. PHOTO Goderich Aircraft |

Centralia Airport was built as part of the British Commonwealth Air Training Plan and began as the home of the Number 9 Service Flying Training School on Sept. 21, 1942. Pilots were trained primarily for the Royal Canadian Air Force, but also for other Commonwealth nation forces. It was renamed RCAF Station Centralia in September 1947, and remained as such until its closure on March 31, 1967. During its military life, Centralia was the home to various aircraft types, including Ansons, Dakotas, Expeditors, Harvards and, latterly, Chipmunks. The airport was later renamed Huron Air Park and became an industrial park, where numerous light manufacturing companies developed operations.

As far as aircraft activity was concerned, Centralia became a quiet country airfield. Strangely out of place among the resident taildraggers was the occasional sight of a large Grumman Gulfstream II jet, when U.S. Steel executives would drop in to inspect its Hughes Boat Works affiliate between 1969 and 1977. Who would ever have thought that three decades later even larger bizjets would frequent the place?

This is now…

Over the past 13 years, Goderich Aircraft has seen its headcount triple to approximately 150. During this time hundreds of aircraft have been processed. This has included some 40 models from such manufacturers as Boeing (BBJ); Bombardier (Global 5000, Challenger 604, Learjet 55/60, Dash 8); Cessna (Citation I/III/VII); Dornier (328JET); Douglas (DC-9-87); Fokker (F-28-4000); Gulfstream (IV, G550); and Hawker Beechcraft (125-700/800/1000, 1900D, King Air 300). In order to differentiate itself amongst the many North American aircraft refurbishment outfits, Goderich has focused on the upper end of the market – narrow-body airliners.

|

|

| a lavatory aboard a Global 5000. PHOTO Goderich Aircraft |

While this has resulted in a decline in the number of aircraft worked on in a given year, it has served to increase both the number of hours worked and revenues generated. This year, Goderich is expected to complete some 25 projects. The work can be as limited as a new paint scheme, or can be far more complex, involving a complete interior conversion, a cockpit upgrade and a new paint job – all done while the aircraft undergoes a heavy maintenance check. Such a program on an aircraft like a Boeing BBJ can require 120,000 hours of work over seven months.

Goderich Aircraft’s expertise can be segmented into the following four categories:

Interiors – The company has developed a reputation for converting the interior of airliners from mass transportation vehicles into flying penthouses. In addition to airliners, the company has performed interior makeovers for jet and turboprop business aircraft of all sizes. The company has regulatory approvals from Transport Canada, the U.S. Federal Aviation Administration, the European Aviation Safety Agency and the U.A.E. General Civil Aviation Authority that enable it to attract business from geographic markets that represent the bulk of business aircraft operators worldwide.

Exteriors – Whether it is a minor touch up or a completely new look that the customer requires, Goderich is able to strip, prime and repaint aircraft within its modern climate-controlled paint booth that meets all environmental requirements.

Maintenance – Besides being able to make aircraft compliant with service bulletins and airworthiness directives, the company performs heavy maintenance on airframes while they are undergoing interior modifications. Goderich has also completed intricate structural repairs on aircraft. An example of this work is the complete reconstruction of an IAI 1125 Astra that had an I-beam punched through its fuselage after a hangar collapse in Texas. Goderich has also rebuilt the one-piece wing on two Cessna 525 Citation CJ aircraft.

Avionics – The company is well versed in the latest avionic technologies as it is a dealer for numerous leading manufacturers, including Honeywell, Rockwell Collins, Bendix King, Garmin, Aircell, S-TEC Cobham, Universal Avionics Systems and L-3 Avionics Systems. These relationships enable Goderich to perform a wide range of avionics work, including upgrades to navigational systems and the installation of sophisticated in-flight entertainment systems.

In addition to its two hangars that provide it with 115,000 square feet of space, the company has an upholstery shop and a cabinetry operation in Brantford, Ont. Its airport, now named Centralia-James T. Field Memorial Aerodrome, has two hard surface runways (5,012 ft. x 100 ft. and 4,400 ft. x 150 ft.) that can accommodate narrow-body jet airliners.

In order to better understand any business model and therefore appreciate how a company may fare in the future, it is useful to perform a S.W.O.T. analysis (Strengths, Weaknesses, Opportunities and Threats). Doing so with Goderich Aircraft provides the following insights:

S.W.O.T. ANALYSIS OF GODERICH AIRCRAFT

STRENGTHS

INTERNATIONAL REPUTATION

Despite the absence of an extensive advertising campaign, details of the company’s work have been transmitted via word of mouth far afield. This has been a powerful marketing tool that has assisted its efforts in winning new customers from around the world. Approximately 95 per cent of its business is foreign.

COMPREHENSIVE SERVICE OFFERING

Goderich’s breadth of technical capabilities, which cover interior design and engineering as well as airframe and avionics maintenance, enables the company to complete complex multiple tasks while an aircraft is in its facility. This “one stop shop” simplifies administrative issues for the client and can result in the aircraft being out of service for a shorter period of time.

CONSTRUCTIVE CORPORATE CULTURE

Highly skilled and well motivated employees are key to any successful business and Goderich makes an effort to attract and retain talent. As Blaine Field notes, “We hire attitude, then train.” The result is low annual turnover among the staff. The workforce is non-union.

Out of the way, but not isolated, is one way to describe Huron Park’s location. With little conflicting air traffic, there is no problem with a DC-9 doing “touch and go’s” during a test flight. Airport costs are extremely reasonable.

For the employees, the area offers a pleasant lifestyle with an attractive cost of living. For those wishing city life, London is only a 45-minute drive to the south.

WEAKNESSES

SOURCING ADDITIONAL TALENT

Capable people with specialized skills are a prerequisite for achieving continued success. While the company has been able to retain talent, it will need to expand its team if it is to meet its growth targets. To assist in this effort, Goderich has recently completed an aerospace manufacturing training centre on its property. The Government of Canada has assisted with $1.3 million of funding and Fanshawe College of London has certified the curriculum and issues Certificates of Training. The program is expected to produce more than 200 new hires for Goderich over the next four years, including about 20 this year.

LOW PUBLIC PROFILE

Despite being appreciated by its clients, many of whom are repeat customers, the company is not widely known within the North American business aviation industry. Developing a greater presence could assist in attracting even more business. We may be hearing more from Goderich in the future.

OPPORTUNITIES:

BBJ COMPLETIONS

Goderich is about to become a Boeing licensed completion centre for new BBJs. It hopes to deliver its first “green completion” by the end of next year. This is quite a vote of confidence for Goderich, as there are only 10 completion centres listed on the Boeing Business Jets website.

REPLACEMENT MARKET UPGRADES

When large-cabin VIP aircraft change owners, be they airliners or purpose-built types, usually there is demand for interior, exterior and avionics modifications. As the global economy recovers, the pace of such activity is forecast to increase.

THREATS:

COMPETITION

Local competitors such as Sky Harbour Aircraft in Goderich, Ont., and Flying Colours in Peterborough, Ont., have long provided quality aircraft interior and exterior refurbishment services. While both have worked on general aviation aircraft, including large business jets such as Falcons and Gulfstreams, they have also pursued specific niches. Sky Harbour has developed a reputation related to War Birds – former military aircraft owned by civilians. Flying Colours has become a specialist in the conversion of Bombardier regional jets into corporate jets and is now doing “green completions” for buyers of the Challenger 850 model.

Goderich Aircraft’s primary competitors are the aforementioned international players in the U.S., Germany, Switzerland and France. The fact that Goderich has received contracts from clients located in the Middle East and Africa, despite the efforts of established competitors, speaks volumes about its ability to compete on the world stage.

STRONGER CANADIAN DOLLAR

For many Canadian companies that do most of their business with foreign customers, a stronger Canadian dollar is a negative development. Goderich deals with this dilemma by pricing most of its contracts in the U.S. currency. It also helps that most of its material costs are priced in U.S. dollars.

What does this all mean?

Without making a lot of noise, Goderich Aircraft has steadily gone about building its business by providing a quality product in a timely manner at a desirable price. By doing so it has developed an impressive list of international clients, many of whom have come back to have work performed on additional aircraft. It has also chosen to go after a segment of a luxury market that is somewhat less susceptible to the vagaries of the global economy.

|

|

| A pair of Douglas DC-9-87s in one of Goderich Aircraft's pristine hangars. Photos: Goderich Aircraft |

In order to meet the potential that lies ahead, Goderich has decided to enhance its human capital by creating a training centre that will provide the additional skilled personnel that it needs. The expansion of its bricks and mortar, which will be necessary in order to achieve its growth aspirations will likely attract funding, now that the availability of manpower should be less of an issue.

Future prospects

Having grown from a crew of five to a team of 150 since its inception in 1993, Goderich Aircraft has achieved steady growth as it advanced its capabilities. Blaine Field expects the headcount to further increase to 250 over the next year or so. Five years from now, he sees the company employing 400 people. That could translate into annual revenues of approximately $70 million, up from a little more than $20 million in 2009. To handle the increased level of throughput, Goderich will be adding a third hangar. With an additional 60,000 sq. ft., it will boost the company’s workspace by 52 per cent.

|

|

| A Bombardier Global 5000 on the ramp at CYCE. Photos: Goderich Aircraft

|

The funding of this expansion will, in part, be done using the more than $4.4M that the company recently received from the Federal Economic Development Agency for Southern Ontario (FedDev Ontario). Upon learning of the federal government’s decision to assist Goderich Aircraft, Field commented, “We’re excited to be entering a phase of dynamic growth that will strengthen the relationship that we are building with Boeing and allow us to bring new business from international markets to southern Ontario. Thanks to the federal government’s commitment to Canadian manufacturing and its investment in the region, Goderich Aircraft is now positioned to begin work completing Boeing Business Jets.”

Final thoughts

While the corporate/VIP airliner market is not immune to the economic cycle, the majority of its constituents (governments, large private companies and wealthy families) tend to have greater staying power during periods of financial turmoil. In fact, some operators use such downdrafts as an opportunity to upgrade their aircraft. When that occurs there is often a requirement for changes to the interior and exterior of the aircraft.

Goderich Aircraft has chosen to focus on this international niche market and the customer response has been rewarding. The company’s mission statement is straightforward: “Provide a cost-effective quality product.” This is done by fielding a talented team that is equipped with a broad range of technical expertise and can deliver a product that meets the customers’ needs based on design, finish and performance. Having accomplished that, the good folks at Huron Park should see many more metallic beasts touch down at their placid rural setting.