News

Products

SyncroFIT 2009

June 10, 2009 – Vistagy Inc., a leading provider of industry-specific engineering software and services, has announced the release of SyncroFIT 2009, which improves the efficiency and accuracy of assembly development by enabling commercial 3D CAD users to fully define and manage joints and interfaces between parts within complex assemblies.

June 10, 2009 By Administrator

|

|

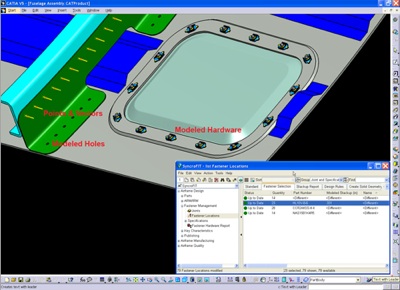

| SyncroFit 2009 enable engineers to visualize the airframe assembly at a level commensurate with the task at hand. Pictured are three levels of detail. During the assembly design and fastener layout phase, simple point and vector representations of fasteners are usually sufficient. At other times, visualizing modeled holes are needed to asses manufacturability. If a more comprehensive view is necessary – such as for performing clash/interference detection Syncrofit 2009 enables the user to load fasteners so that all modeled hardware can be seen, including nuts, washers and nut plates.

|

June 9, 2009 — Vistagy Inc., a leading provider of industry-specific engineering software and services, today announced the release of SyncroFIT 2009, which improves the efficiency and accuracy of assembly development by enabling commercial 3D CAD users to fully define and manage joints and interfaces between parts within complex assemblies. The solution enables engineers to specify fasteners and holes, rapidly load catalog parts and validate adherence to design rules when creating large aerostructures. SyncroFIT can be used individually or as part of the Vistagy AeroSuite, a comprehensive solution that enables aircraft manufacturers to effectively manage the product development process and deliver optimized parts and assemblies in less time at lower cost.

Defining joints and interfaces presents common and costly bottlenecks in the airframe assembly design process and is a leading source of manufacturing errors. For example, managing the nearly two million fasteners in an aircraft has traditionally been a manual process plagued by inaccurate fastener definitions and difficulty making design changes. Approximately 40 percent of design changes are due to errors in the authoring of the initial assembly interfaces. At up to $20,000 per engineering change order, using SyncroFIT to avoid these errors translates into several million dollars in savings. The commercial CAD system alone doesn’t give engineers the specialized functionality they need. But SyncroFIT works within the CAD system to enhance the accuracy and efficiency of the design process and provide an early warning of potential issues in the manufacturing process so OEMS and suppliers can meet demanding delivery schedules.

Engineers need effective tools for visualizing the airframe assembly at the appropriate level of detail for the task at hand to work efficiently and obtain the necessary insight into the development process. Vistagy has consequently created functionality that enables the user to toggle between different visualization states. During the assembly design and fastener layout phase, simple point and vector representations of fasteners are sufficient to communicate key information quickly. At other times, clearance solids—such as cylindrical fastener representations or tool envelopes—are necessary to assess manufacturability by visualizing potential interferences that could occur during assembly. But if the task is to perform complete clash/interference detection, maintenance or installation studies, or if it is a required supplier deliverable to the OEM, it is necessary to load fasteners into the model so all the hardware can be seen, including nuts, washers and nut plates. To do this, engineers need to visualize the assembly populated with solid model representations of the fastening hardware and have the ability to easily delete or select different fasteners and associated hardware to meet design specifications.

SyncroFIT automatically loads fasteners and hardware from the parts catalog into the 3D model with the push of a button, taking only minutes to do what can take days using a manual process. Customers have experienced up to an 80 percent reduction in time to define fasteners using this functionality alone.

In addition to the unique visualization capability, SyncroFIT provides a number of fastener related design checks, including edge distance and pitch, countersink depth, angularity and length-to-diameter ratio. Verifying that design rules are met throughout the iterative development process ensures that commonly occurring errors are caught prior to design release. These rules enable enhanced communication between design and analysis to expedite the design review process.

The lack of a standardized process for defining conditions of supply is another factor that has historically caused a high level of rework. SyncroFIT remedies this problem by providing a clear definition of the deliverable state of the component to make the assembly process easier and to ensure clear communication between supply chain partners. The software simplifies the process of conveying changes to suppliers, ensures the product is manufactured properly and saves valuable time.

“Our in-depth experience in the aerospace industry enables us to develop software that supports the engineering challenges at different points in the development process,” said Bob Flory, vice president of product development at Vistagy. “SyncroFIT 2009 allows design information to be captured and leveraged more completely throughout the entire development process, making it more efficient and less error-prone. As a result, airframe developers are far better able to deliver parts and assemblies in a timely and cost-effective manner.”

About Vistagy

Vistagy, Inc. is a leading global provider of engineering software and consulting services that optimize product development processes by enhancing the functionality of commercial 3D CAD systems. For almost 20 years, Vistagy has been a pioneer in providing industry-specific solutions that capture complete virtual product definitions and facilitate automatic reuse and efficient exchange of engineering information across the enterprise and supply chain. Vistagy solutions help customers deliver robust products on time and on budget by increasing productivity, improving communication throughout the product life cycle and enabling better-informed decision-making early in the design process. The company's customers include over 200 of the world's leading manufacturers in the aerospace, automotive, transportation interiors and wind energy industries. Vistagy is headquartered in Waltham, Massachusetts, USA and can be reached at +1.781.250.6800 or by visiting www.vistagy.com .