Features

Operations

The Standard for Strategic Airlift

The Boeing C-17 Globemaster III has marked out a prominent spot among today’s spectacular mastodons of the air.

November 27, 2009 By Philippe Cauchi

The Boeing C-17 Globemaster III has marked out a prominent spot among today’s spectacular mastodons of the air. In a select group that includes the Lockheed C-5 Galaxy, the Antonov An124 Ruslan and the An225 Mriya, the C-17 represents the modern standard for strategic airlift.

|

|

| The Canadian C-17 has been designated the CC-177 Globemaster III –“CC” for “Canadian” and “Cargo/Transport.” It is the only aircraft that can transport and deliver heavy and bulky loads close to the battlefield.

|

Its bulky silhouette has been seen during peacekeeping operations in Bosnia, war operations in Kosovo, Eastern Timor, Iraq and Afghanistan, as well as humanitarian missions following the tsunami of 2004, Hurricane Katrina in 2005, Cyclone Nargis in Myanmar in May 2008 and the conflict in Georgia in August 2008.

This four-jet-engine widebody high-wing T-tail airlifter draws its name from two other transport aircraft that served in the U.S. air force: the Douglas C-74 Globemaster, prominent at the time of the Berlin Airlift, and the Douglas C-124 Globemaster II, prominent during the Vietnam War.

Since its entry into service within the U.S. air force in 1995, Globemaster III, which has accumulated more than one-and-a-half million flight hours, remains the only military cargo airplane able to carry troops and bulky loads on long distance trips directly to the zones of operations. Its capability in operating from short, unprepared landing strips makes such trips possible.

Troubled beginnings

In the ’70s, the U.S. air force considered the replacement of the Lockheed C-130 Hercules. This led to the development of the Advanced Medium STOL Transport (AMST) program. Both the Boeing YC-14 and McDonnell Douglas YC-15 were designed for the project, but neither got beyond the stage of flying prototypes because of the urgent need for a new strategic airlifter.

The “New Cargo Experimental C-X” contest was launched to find a replacement for the growing older fleet of more than 200 Lockheed C-141 Starlifters.

|

|

| The C-17 requires only three crew members: a pilot, a co-pilot and a “loadmaster.”

|

On Aug. 28, 1981, St.-Louis based McDonnell Douglas was chosen to develop, on the basis of YC-15, an all-new wide-body cargo aircraft able to reach any point on the planet and to use unprepared landing strips. In December 1985, a contract for 210 C-17A Globemaster IIIs was signed, a number that was reduced to 120 in April 1990.

Eighteen months late, the C-17 prototype undertook its inaugural flight on Sept. 15, 1985, from the Long Beach airport adjacent to a facility especially set up by McDonnell Douglas for the Globemaster III. The flight test program went so wrong that the Department of Defense thought of shrinking the order to 40 aircraft.

The first production C-17 was finally delivered June 14, 1993, to the 17th Airlift Squadron in Charleston AFB, in South Carolina. The squadron was declared operational on Jan. 17, 1994.

In 1998, the USAF increased its order to 134 aircraft, then, in August 2002, to 180. The 2007 DOD budget included funds for 10 additional planes. On Feb. 6, 2009, funding was approved for an additional 15 C-17s, increasing the total ordered by the USAF to 205, and ensuring the assembly line will remain open until August 2010. On June 8, 2009, the U.S. Senate approved the FY09 Supplemental Defense Spending bill with funding for eight C17s. If the current legislations passes, the USAF’s total order would rise to 223 aircraft.

An outstanding design

Designed from technologies developed for the YC15, the C-17 is a high-wing, four-jet-engine T-tail wide-body cargo plane. With a wingspan of 51.75 metres, a length of 53 metres and a height of 16.8 metres, it has a maximum take-off weight of 265 tons and flies in cruise at 13,500 metres at 830 kilometres per hour. Its 27-metre-long, 5.48-metre-wide and 3.76-metre-high cargo hold can transport up to 77 tons of equipment on 18 pallets, or 102 parachutists, or in medical transport configuration 48 litter and 54 ambulatory patients. It can accommodate loads as heavy as a 70-ton Abrams M1 tank or as bulky as a Boeing CH-47 Chinook helicopter.

|

|

| On Oct. 18, 2007, the second CC-177 joined CFB Trenton, while Boeing delivered the third and the fourth respectively on March 26 and April 3.

|

With a payload of 72 tons, the operating range of Globemaster III without in-flight refuelling reaches 4,500 kilometres. Powered by four Pratt & Whitney 40,400lb thrust F117-PW-100 engines (military designation of the PW2040 which equips the Boeing 757), the C-17 can use runways as short as 3,000 feet and as narrow as 90 feet.

The C-17 requires only three crew members: a pilot, a co-pilot and a “loadmaster” while the C-5 and the C-141 each require two pilots, a navigator, two mechanics and two loadmasters. Its design called mainly upon off-the-shelf-systems. The C-17 borrows the cockpit of the DC-10. It was ahead of its time by its rather important use of composites, which amounted to 16,000 pounds on an empty weight of 282,000 pounds. The C-17’s life expectancy was fixed at 30,000 hours on the basis of 1,000 hours per year. Since the beginning of the operations in Afghanistan and Iraq, the annual flight hours average is closer to 1,400.

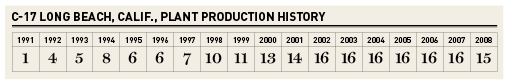

The C-17 Long Beach, Calif., plant can produce between 15 and 16 airplanes per year. With 5,000 employees and 990,000 square feet, it is also in charge of the construction of the wing and three sections of the fuselage, as well as pre-delivery tests and delivery. The C-17 program has created employment for 25,000 people at Boeing and another 700 with its suppliers.

Into its 18th year in production, the configuration of C-17 Globemaster III has changed very little. The C-17 Block 18, the very last version, does not differ significantly from its predecessors, apart from the communication systems.

The following USAF bases house C-17 squadrons: Charleston AFB, McChord AFB, Altus AFB for the training of U.S. and international crews, Jackson-Evers International Airport ANGB, McGuire AFB, Elmendorf AFB, Hickam AFB, Travis AFB, March Air Reserve Bases and Dover AFB.

The Globemaster III has accumulated 33 world records, more than any other transport aircraft. In May 1995, the C-17 received the most prestigious distinction in the world of the aviation, the Robert J. Collier Trophy, awarded by the National Aeronautics Association (NAA). In February 1999, then-president Bill Clinton awarded the prestigious Malcolm Baldrige National Quality Award to the Boeing Airlift and Tanker Programs team for “excellence in business.”

C-17 international operators

Royal Air Force • In May 2000, the Royal Air Force announced a seven-year lease for four C-17s to fill the gap created by the progressive withdrawal of the oldest C-130 while waiting for the delivery of 25 Airbus A400M. Very pleased with the leased aircraft, the British government decided on July 21, 2004, to buy them. The acquisition of a fifth aircraft was made public on Aug. 4, 2006, and of a sixth, on July 26, 2007.

|

|

| Canadian Aviation Technicians learn the C-17 flight deck operation and maintenance, avionics, communications, and flight controls in the Trainer Evaluation Performance Aircraft Training Set (TEPATS) at Charleston, Va.

|

The RAF took possession of its first C-17 on May 17, 2001, and of its sixth, on June 11, 2008. They all are attached to RAF Brize Norton base, 80 kilometres west of London.

Royal Australian Air Force • In order to meet the needs for projection of its armed forces following the Timor incident, the Australian government, in March 2006, placed an order for three C-17s accompanied by an option. The first Globemaster III was delivered to the Royal Australian Air Force on Nov. 29, 2006, and the last, on Jan. 19, 2008.

Several other countries, including Israel and Japan, expressed an interest in the Boeing C-17. On July 21, 2008, Boeing announced the sale of two C-17s to the government of Qatar, delivered in August and September 2009. On Nov. 24, 2008, 12 NATO countries made public the acquisition of two C-17s, the first of which was delivered on July 27, 2009. In February 2009, United Arab Emirates ordered four C-17s.

Civil version of C-17

In the middle of the 1990s, McDonnell Douglas proposed a civil version of C-17, the MD-17 renamed BC-17 following its merger with Boeing in 1995.

In March 2007, an obscure company named Total Heavylift Holdings announced its interest in purchasing about 30 C-17s. That led Boeing to resurrect the program around the time of the 2007 Paris Air Show.

Canada and the C-17

In order to airlift the DART team and its equipment to Sri Lanka following the December 2004 tsunami, Canada had to rely on leased Antonovs and Ilyushins. Canadian Forces depended entirely on Antonov An124 Condors to deploy in Haiti in 2003, and on An124, Ilyushins It-96s and USAF C-17s to convey heavy equipment in Afghanistan.

In this context, the Canadian Forces Future Strategic Airlifter Project was set up in 2002 to study solutions in order to modernize the air transport capabilities of the Canadian Forces. On June 29, 2006, Minister of Defence Gordon O’Connor and Chief of Staff Gen. Rick Hillier, made public the request for proposal for four strategic transport aircraft and 17 transport aircraft tactical. The estimated total cost of the purchase of the four strategic airlifters is $1.8 billion to which a 20-year support contract estimated at $1.6 billion will be added.

These were the requirements:

- To be able to carry 39,000 kilograms over 6.482 kilometres unrefuelled.

- To be capable of taking off and landing on a 1,219-metre-long and 27-metre-wide unprepared runway.

- To offer a 27-metre-long, five-metre-wide and four-metre-high cargo area allowing the transportation of NATO pallets as well as of wheeled equipment in combat-ready configuration and helicopters with only minor disassembly and without the need for loading equipment.

To be certified at the date of signing the contract, the first aircraft had to be delivered 18 months after the signing of the contract, and the last, at the latest, 48 months after the signing of the contract.At that time, for strategic airlift, Canada relied on the five CC-150 Polaris, modified Airbus A-310 jetliners, which were limited because of their restricted capacity, their need for paved runways and their need for loading and unloading equipment.

|

|

| Eventually, the 429th Squadron will be composed of 32 pilots, 24 loadmasters, 105 technicians and 10 maintenance managers. From left to right : Capt. Simon Potvin, loadmasters Adj. Pete Lessard and Master Cpl. Rich Lees. |

According to Air Force public affairs officer Lt. Paul Finnemore, only the Boeing C-17 fulfilled the requirements. The Airbus A-400M with first deliveries not scheduled before 2012, was at the time “a paper airplane.”

On Feb. 2, 2007, the Department of National Defence announced the signing of a contract with Boeing for four C-17s that included the purchase of 18 Pratt & Whitney F117-PW-100 engines, four infra-red countermeasures LAIRCM suites and 20 AN/AVS-9 night vision goggles.

Canadian C-17s carrying the CC-177 Globemaster III designation, “CC” for “Canadian” and “Cargo/Transport,” are the 177th, 180th, 186th and 187th built and have post registration numbers ranging from 177701 to 177704.

In order to prepare for the arrival of the first aircraft, the 429th Transport Squadron “Bisons,” an element of the 8th Wing based at CFB Trenton in Belleville, Ont., was reactivated on June 18, 2007. Under the command of the Lt.-Col. Dave Lowthian, the squadron’s 200 members will be responsible for the operations and the maintenance of Canada’s C-17 fleet.

On July the 23, 2007, “Canada One” made its inaugural flight in Long Beach and on Aug. 11, marked its arrival in Canada by showing up at the Abbotsford air show before joining CFB Trenton the following day.

Two weeks later, the “177701” executed its first mission by delivering more than 32 tons of humanitarian aid to the victims of Hurricane Dean in Jamaica. Two days after its return, the same aircraft left for Afghanistan. Between August and September, it carried out 23 missions, including nine bound for Afghanistan.

On Oct. 18, 2007, the second CC-177 joined CFB Trenton, while Boeing delivered the third and the fourth respectively on March 26 and April 3. The third Globemaster III flew on May 14, 2008, to Thailand with 45 tons of emergency aid for the victims of the Cyclone Nargis that struck neighbouring Myanmar.

A new era

As Col. Michael Hood, commander of the 8th Wing at CFB Trenton, explains, the C-17 has opened the era of strategic transport for the Canadian Forces. Colonel David Lowthian, commanding officer of the 429th transport Squadron, says that the C-17 is the only aircraft able to fill tactical and strategic transport missions because of its ability to transport and deliver heavy and bulky loads close to the battlefield.

The Globemaster III can carry up to 18 NATO pallets for a maximum load of 170,000 pounds or 143 passengers and two pallets for the luggage compared to six NATO pallets and 300,00 pounds for the C130. Its ramp is 18 feet wide, only a foot less than the C-5 Galaxy, but five more than the A-400M.

On a typical mission, a Canadian Forces C-17 will take off with a load of between 90 and 100,000 pounds, fly at an altitude of between 33,000 and 38,000 feet, at a cruising speed of 450 knots – four to five times what a Hercules can carry and 50 per cent faster.

The flights in support of Canadian troops in Afghanistan are carried out in three stages, starting from CFB Trenton: a first to Spangdhalem AFB in Germany, a second to Camp Mirage in the Persian Gulf and the last to the Kandahar airport, where the refuelling capabilities are very limited. There, the C-17 hardly remain more than two hours on the tarmac.

Starting in July 2008, three flights were made every month to Afghanistan. Currently, it is four and soon it will be seven, said Lt.-Col. Lowthian.

Two hangars, one for maintenance and the other for support for the operations, each able to shelter one Globemaster III, will be built at CFB Trenton for 2012. In the meantime, the Squadron personnel carry out the maintenance of the aircraft at Jackson ANGB of the Mississippi Air National Guard. Every four months, each C-17 remains there for seven to 11 days.

The arrival of the CC-177 required the purchase of new 60,000-pound, or eight-pallet, loaders. Canada, like all current C-17 operators, is part of the “C-17 Sustainment Partnership” managed by Boeing, which allows for common management of the spare parts.

The Canadian Forces C-17 should reach the 5,000 flight hours per year mark. For the moment, it is more likely around 4,000 with a readiness rate of 84.6 per cent, which is in line with the USAF C-17.

Eventually, the 429th Squadron will be composed of 32 pilots – including 16 commanders and 16 first officers – 24 loadmasters, 105 technicians and 10 persons in charge of maintenance management.

The majority of the C-17 pilots come from the CC-130 or the CC-150 with between 1,200 and 9,000 flight hours, some from the CP-140 Aurora, one or two from the CF-18 Hornet and eight directly from the flight school.

The flight training, which lasts between three and four months, takes place at Altus AFB in Oklahoma and includes integration into a USAF unit.

Economic offsets

In January 2008, in order to conform to the requirements of the Canadian Industrial and Regional Benefits (IRB), Boeing made public a first series of contracts with the Canadian aerospace industry amounting to $795 million.

The Seattle airframe manufacturer had then identified 66 per cent of its IRB that must correspond to 100 per cent of the value of the purchase of the C-17.

Boeing already has in Canada its centre of excellence in composites with its Winnipeg facilities, which employ more than 1,500 people and produce more than 2,500 different parts. Many of these parts are major elements of the Boeing 787. Boeing has also acquired two companies specializing in software designed for the air transport industry: AeroInfo of Richmond, B.C., and Carmen Systems of Montreal.

Not including the C-17 contract, Boeing annually purchases more than $800 million of products from some 200 Canadian aerospace companies. With all of its purchases included, Boeing injects $1 billion a year into the Canadian economy.

|