Features

Aircraft manufacturers

The Experience Engine, Inside the Pratt & Whitney PT6 E-Series

“We looked at it as raising the bar on engine performance control systems, data intelligence and service solutions; and wrapping everything together as one.”

January 13, 2020 By Jon Robinson

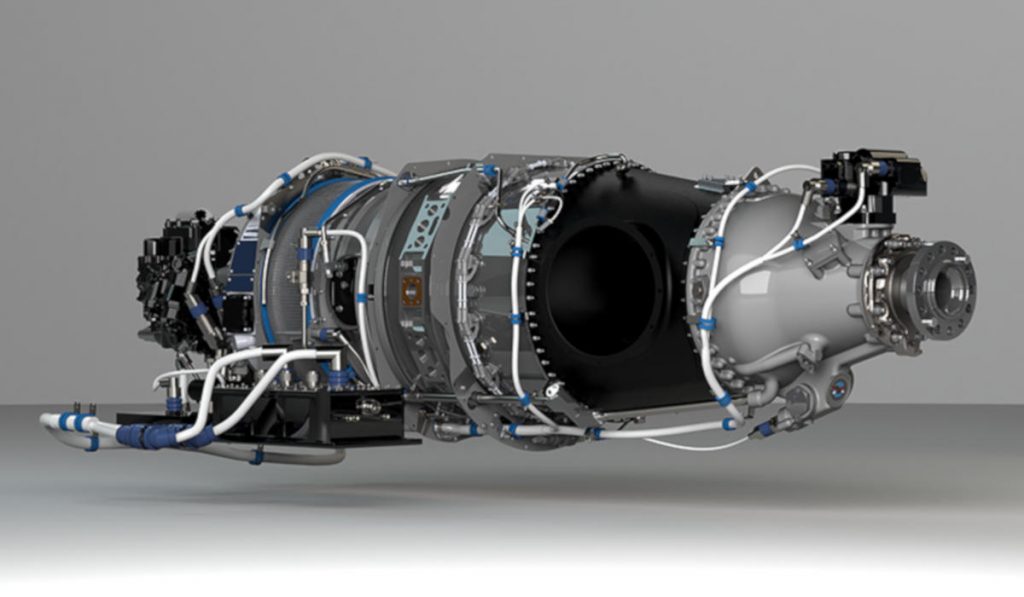

The PT6E-67XP turboprop engine from Pratt & Whitney features an Electronic Propeller and Engine Control System including Full Authority Digital Engine Control (FADEC) – a worldwide first in the business aviation sector. (Image: Pratt & Whitney)

The PT6E-67XP turboprop engine from Pratt & Whitney features an Electronic Propeller and Engine Control System including Full Authority Digital Engine Control (FADEC) – a worldwide first in the business aviation sector. (Image: Pratt & Whitney) Pratt & Whitney at NBAA in October 2019 celebrated the introduction of its new PT6 E-Series engine in conjunction with Pilatus unveiling its PC-12 NGX single-engine turboprop. This aircraft represents a third generation of the PC-12 airframe and, therefore, more than 30 years of development from a global fleet of over 1,700 aircraft with more than seven million total flight hours. If those numbers are staggering for one of the most-successful turboprops on the planet, consider the PT6E-67XP powering the NGX is developed from the iconic PT6 engine that first flew out of Toronto’s Downsview Park in May 1961 and has now amassed close to a half billion hours of operational flight time.

Those PT6 hours are counted among a total 1.5 billion hours of Pratt & Whitney engine time since the operation’s founding in 1925. Pratt & Whitney Canada (P&WC), a unit of Pratt & Whitney, which is owned today by United Technologies Corp. (UTC), focuses on business, general and regional aviation, as well as helicopters and APUs. P&WC’s rich history of fostering both engine innovation and maturation is a key piece – along with UTC-owned Collins Aerospace – of the pending all-stock merger between UTC and Raytheon Company.

P&WC engines – with approximately 65,000 in service – are being used by more than 13,900 customers, including over 1,100 airlines, in 200-plus countries and territories. One of the operation’s taglines states, “Every second, a Pratt & Whitney-powered aircraft takes off or lands somewhere in the world.” Expected to close in the first half of 2020, the UTC-Raytheon merger would create a defence-and-aerospace giant generating annual revenues of approximately US$120 billion ($158 billion in Canadian funds), according to a June 2019 Reuters report. It would presumably provide P&WC with a treasure trove of new technology insights to build its engines; and potentially an even larger research-and-development (R&D) budget.

Approximately 6,000 of P&WC’s 10,000 global employees are based in Canada, including around 1,500 specialized positions at P&WC’s two primary R&D centres in Longueuil, Quebec, and Mississauga, Ontario. P&WC – ranked this year as one of Canada’s top five R&D investors by Research Infosource – has invested well over $1.3 billion from 2014 to 2019 to develop new-generation aircraft engines. The Longueuil team received a bulk of that investment to develop the PT6 E-Series engine with world-first engineering goals. This includes the PT6 E-Series’ position as the first turboprop engine in general aviation to offer a dual-channel integrated electronic propeller and engine control system, including Full Authority Digital Engine Control (FADEC). The digitized PT6 E-Series is a step-change for operators, maintainers and pilots in terms of service and pure engine advancement.

Digitizing the iconic PT6

The PT6 E-Series engine was engineered to provide pilots with a more intuitive way of flying with precise, single-lever control – eliminating the typically complicated multi-lever operation of turboprops – and to also provide maintainers with rich data for predictive analysis of the engine and system operation, ultimately leading to longer maintenance intervals. Operators, as a result of these PT6E-improved pilot and maintainer conditions, will inherently realize cost savings.

“We looked at it as raising the bar on engine performance control systems, data intelligence and service solutions and wrapping everything together as one,” says Nick Kanellias, VP of marketing for general aviation at P&WC, whose team oversees the PT6 E-Series program in terms of customer service and core engineering support. “It’s not about one individual portion. It’s about how the whole value offer for each one of these stakeholders.”

Kanellias has been working with the PT6 E-Series team for three years now and with P&WC’s PT6 group for 10 years, since joining the company in 2009 to help lead its helicopter engineering program. P&WC’s first PT6 dual channel FADEC on a turboshaft was applied through the PT6C helicopter engine to deliver improved fuel burn, ease of maintenance and better engine handling. Its resulting power boost enabled an Airbus H175 – a 7-ton-class, super-medium-utility helicopter – to achieve a time-to-climb record reaching 6,000 metres in six minutes and 54 seconds during pre-certification testing.

“We chose to go to dual-channel that incorporated full features to have enough redundancy to control the propeller as well as the engine, so that you can continue to operate if sensors or other features went offline or started to drift – anything could happen. We monitor all of these parameters so we can trend them and understand what’s going on all of the time,” says Kanellias. “If you’re going to meet the [goal of] no rigging, no mechanical backup, no backup period, you need to make sure your electronics are fully redundant and that’s why we used two independent controls.”

P&WC also has a track record with PT6 electronic control, primarily with integration on trainer aircraft, as well as with some earlier engines and a previous prop control. “We asked what more can we do to enhance reliability and make sure [PT6E held] the exacting standards of a PT6, which is focused on reliability, safety, and the ultimate value of customers feeling comfortable when getting into an aircraft with our engines,” says Kanellias. “We hold that kind of vision in high regard. When we created this concept, it was about a customer experience… The PT6 E-Series engine is actually about an experience series – it also happens to be electronic.”

P&WC early on in PT6 E-Series development committed to building a new Electronic Engine Control (EEC) , a continuation of the company’s tradition of evolving the PT6 for future needs. “We have had a vision for doing an electronic control for a while now. It had to meet our standards for this market segment. We can’t just take an electronic control from somewhere else and put it into this segment,” says Kanellias. “When you can consider what we’ve done here, it is really a step-change in terms of experience for the pilot, the maintainer and the owner-operator of the engine and aircraft. It changes how the pilot sees information, how the maintainer accesses information on the engine, and even how it interacts with our training manuals.”

The PT6 E-Series EEC allows a pilot to start and stop the engine with the push of a button, while being protected against hot and hung starts. The integrated dual-channel electronic propeller and engine control system allows a pilot to command performance from that single lever, as the EEC constantly monitors parameters like temperature, fuel flow and torque to provide optimal power throughout all phases of flight. In essence, the system allows for changes in speed and control of the prop conditions to suit different environments.

The new PT6 E-Series EEC also replaces traditional mechanical controls and linkages with the dual-channel digital electronic system. “All of that combines into a much easier flight experience for the pilot right from the start of the engine to landing and shut down. All of this is done with two independent control systems… achieving it was not easy, but the vision was about changing that experience and how people perceive an electronic control.”

Among the 100-plus engine parameters being monitored by the PT6 E-Series to optimize flight are several sensors allowing the PC-12 NGX to run a new propeller low speed mode. “You set a condition and the engine just drives towards that condition. It doesn’t matter what the prop speed is; and that’s fully integrated in how the powerplant works,” says Kanellias. “The pilot doesn’t need to think about these things. They can focus on flying… the engine will interact with the aircraft seamlessly to accomplish it. That was part of the vision we had at the beginning – how do you make things easier for everyone.”

Kanellias admits the team was not expecting the amount of positive reaction to the PT6 E-Series’ ability to drop the speed down while maintaining the same amount of performance – “It gives people options they never thought they had before.” When Pilatus unveiled the PC-12 NGX, the Swiss aircraft maker pointed to how the propeller low speed mode results in a significant reduction in cabin noise for greater passenger comfort. “You need to be able to provide the right power required throughout the envelope and that is something that took a while; to make sure that we could do it seamlessly, especially with the enabled auto-throttle,” says Kanellias.

The new turbine design of the PT6E-67XP engine model powering the PC-12 NGX aircraft allows for quicker climb, greater speed (based on greater thermal energy), and a 10 per cent increase in power (at sea level) when compared to the PT6A-67P engine model deployed in the current PC-12 NG airframe. The new PC-12 NGX, rated to achieve a maximum cruise speed of 290 KTAS (537 kilometres per hour) is described by Pilatus as the most-advanced, single-engine turboprop ever. Equipped with features like Prist-free fuel operation and Honeywell’s Advanced Cockpit Environment System, the PC-12 NGX holds a 2020 base price of US$4.39 million, with typically equipped executive-configured aircraft priced at US$5.37 million.

Leveraging the PT6 E-Series

The digitization of the PT6 E-Series also provides new conditions for how an operator considers the total cost of aircraft ownership based on engine performance. The new Pratt & Whitney Eagle Service Plan (ESP) has been designed so that owners can benefit from a reduction of at least 15 per cent in hourly engine operating costs, when compared to ESP Gold for PT6A-powered PC-12 NG aircraft. Once the aircraft lands, all of the engine flight data is wirelessly downloaded if an operator has committed to ESP or CAMP Engine Health Monitoring. The significant reduction in hourly engine costs is largely based on providing both operators and maintainers with new insights into the performance and health of the engine. ESP allows for advanced planning of any maintenance needs, but customers can also maximize their operations to reduce costs, flying when they need to and for longer periods.

The PC-12 NGX leverages the new PT6E-67XP turboprop engine for single-lever operation, higher speeds and faster climb, in addition to a range of maintenance benefits. (Photo: Pilatus)

This new data insight is specifically leveraged through on-wing availability provided by the PT6 E-Series’ 600-hour scheduled maintenance interval, which has been increased from 300 hours. The PT6 E-Series also holds what P&WC rates as a 43 per cent longer Time Between Overhaul intervals, which increases to 5,000 hours, as well as a reduction of scheduled maintenance on the engine by 40 per cent.

“We tailored the engine to include much more coverage under the new PT6 E-Series ESP plan; and raised the bar there as well by leveraging the capabilities of the engine,” says Kanellias, noting a key facet of the new ESP provides more proactive peak oil analysis that digs into the details of what’s going on inside the engine. “With the E-Series engine being unique and offering unique details and information, we wanted to complement it with an ESP program… demonstrating that we stand behind a lot of what we have designed here; and taking advantage of it. That’s where we project lower operating costing in using this engine.”

P&WC has created an mobile app to interact with the engine on the ground and understand what’s going on regardless of location, which is another unique and new advantage for both pilots and maintainers to leverage. “You will be able to access key performance data directly from the engine on a phone which can be used to do some of the troubleshooting. You will have access to this information and that is the difference here,” says Kanellias. “You will land wherever you need to be, but as long as you have a phone with a signal, you can always be connected to the engine.”

Customers who enroll in ESP can leverage P&WC’s internal predictive analytics team – dedicated engineers and data analysts – to provide personalized, proactive recommendations to maximize time on wing and to reduce operating costs. “We can take the information and, with our proactive service teams, constantly monitor for changes and trends on any kind of drifts to be able to quickly get back to the customer to address things before they even know that they have issues. That’s also a significance difference for the maintainer. They will get information on the fly from the engine.”

The ESP package – sold through the Pilatus dealer – allows owners and operators to apply their standard operating procedures directly to the aircraft. “They can optimize their operations of aircraft and engine, because we have enough flexibility here so that they can program the system to accomplish it,” says Kanellias. With no minimum flying-hour thresholds, the PT6 E-Series ESP also includes foreign object damage repair and environmental protection, as well as overhaul, scheduled line maintenance, fuel nozzle refurbishment, unscheduled hot section inspection, basic unscheduled repair and accessory repair, among others.

Kanellias emphasizes how the ESP reinforces P&WC’s vision for the PT6 E-Series to make the flying experience simple all around. From a pure engineering perspective of this vision, he explains there have been more than 120 innovations within the PT6 turboprop family that have been leveraged for the new engine from turbine materials and aerodynamic features to gearbox and decompressor design. The PT6 E-Series borrows from both the recent PT6-67P development and the historic, 400-million-plus hours of PT6 operation.

“The PT6 market is very personal. There are so many owner-operators who use it for their business, their livelihood, their families,” says Kanellias, noting the vast range of PT6 operators, but emphasizing the potential for the digitized PT6 E-Series to impact business aviation. “The engine support, reliability, and the technology and innovation, allows us to do more with their aircraft. If I can lead the team to support customers in achieving more based on their aircraft and engine choices, that’s my goal and mission. We’ve been introducing innovations for over 50 years now that are very reliable. It’s a key part of what we do.” | W